Functional Testing

Timteh Electronics Ltd. has a long experience regarding functional testing of electronic devices, especially in the field of avionics. Functional testing refers to a testing procedure of an electronic device connected via a test interface to an Automatic Test Equipment . A test executive is running a test program which verifies how the device functions. This type of testing is often used by the avionic or auto industries.

The development of functional testing systems relies on the following actions:

-

Understanding and documentation of the device to be tested. The electronic units used in avionics are units developed in different times with different technologies and testing documentations. The older units usually have a Component Maintenance Manual including a description of the tests, while the newer ones are providing the tests as an ATLAS program. The ATLAS language is a high level language used for tests description but used also as a test program by more sophisticated test executives. Timteh Electronics has processed all types of documentations and has experience with the ATLAS as it is specified by ARINC 626-3 or ARINC 715.

-

If there is no testing documentation furnished by the manufacturer (most of the times it exists) it is necessary to design the test cases. Analyzing the test cases is important to be able to verify that the stimulus and sensors resources on the tester are sufficient. Sometimes there is necessary to add supplementary resources for testing (specially when the tester is for general use) a specific unit. Timteh Electronics designed and built the needed supplementary resources or designed the entire tester. A very sensitive element of a tester is the connection matrix and the connector with the test interface. In avionics there is an ARINC standard for the connector.

-

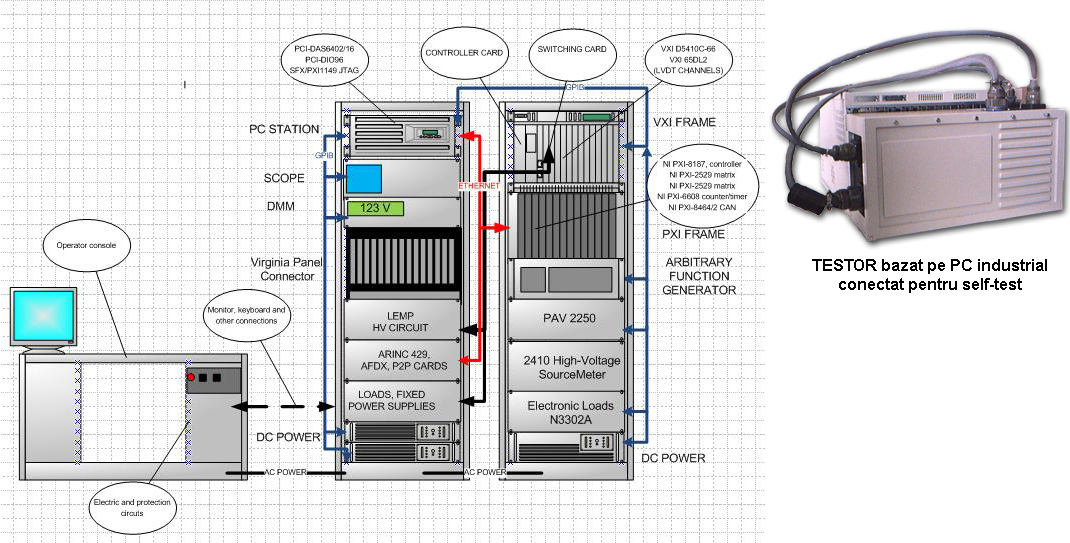

The choice or the design of the tester is linked to the group of devices to be tested. If a general use tester is considered then the base structure of the tester should cover most of the tests. The general use testers are either manufactured by main companies in the field like Agilent, Teradyne, National Instruments, Aerospatiale, Rada Electronic or could be custom built.

Timteh Electronics Ltd. has the knowledge regarding the instrumentation using the GPIB bus or Ethernet or PXI, regarding the connection matrix as wel as the design of drivers for virtual instrumentation . There is also experience regarding communications like ARINC429 or ARINC629 or AFDX.

Timteh Electronics Ltd. has the knowledge regarding the instrumentation using the GPIB bus or Ethernet or PXI, regarding the connection matrix as wel as the design of drivers for virtual instrumentation . There is also experience regarding communications like ARINC429 or ARINC629 or AFDX.

-

Design of the interface between the tester and the unit under test. The interface redirects the connectons between the unit connector and the standard tester connector. Also the interface will host the supplementary necessary resources which are not on the tester. Timteh Electronics has designed hundreds of interfaces for power units, RF units or digital units.

-

Writing the test program using the chosen environment. The test program (TPS) could be written using different high level languages or usual programming languages. The program contains the link with the instruments (through the drivers called by or included in the test executive). Sometimes there is a second layer of drivers for virtual instrumentation which connects real instrumentation to standard virtual instruments.(used by the environment). Timteh Electronics has developed test programs in different programming environments as PAWS, TestStand and using laguages like ATLAS C, C++. The figure presents the graphic interface for a standard DMM which could be connected to different real devices from different manufacturers.

- The integration and validation of the above components by multiple test verification on a number of tested units. The integration is the most important step in the process of validation of the test program and of the interface. The integration is a long process verifying simultaneously the testing hardware and the test program for each test case. Timteh Electronics has performed over 200 integrations for different airplanes like B777, Airbus, etc.